Jinan Carman International Trade Co., Ltd. is a professional manufacturer of internal combustion engine cylinder head products. It is a standing director unit of China internal combustion engine industry association and China Foundry Association. In 2014 and 2018, it won the title of "top 100 comprehensive enterprises and leading enterprises in sub industries" of China Foundry

Association for three consecutive times, In 2014 and 2017, it won the title of "leader in China's internal combustion engine industry" by China internal combustion engine Association. In 2013, it was listed in the first batch of National Foundry Enterprise Access announcement. The company has 960 employees, including 265 engineering and technical personnel, covering an area of 300000 square meters and having fixed assets of 500 million yuan. It has 16 machining production lines, 5 cleaning lines, a

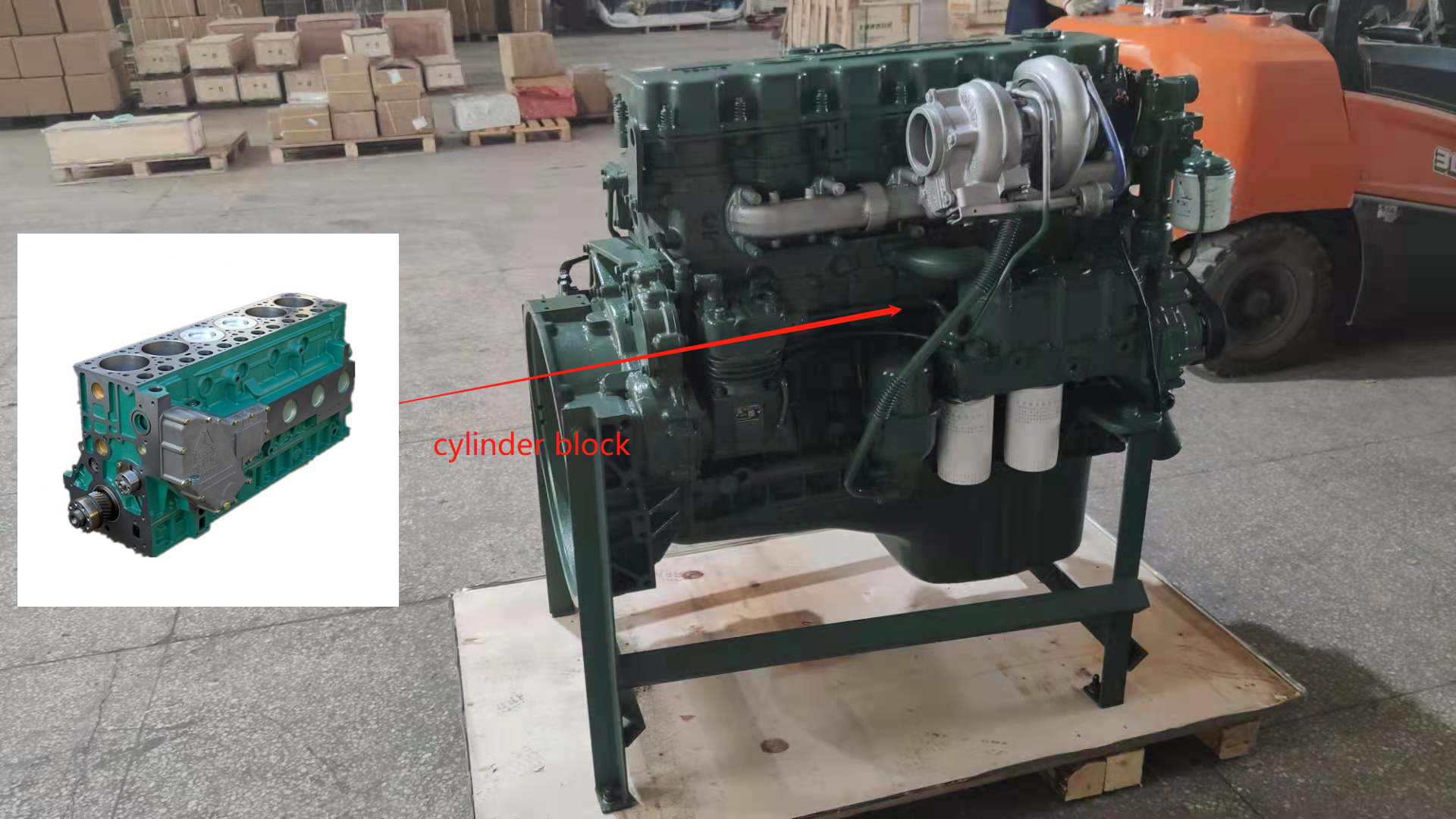

German HWS casting full-automatic molding line and a casting mechanized molding line, and a set of Italian Sima insulation automatic casting system. It has an annual production capacity of more than 1.3 million sets of gray cast iron, vermicular cast iron and aluminum alloy cylinder head products and a casting capacity of more than 60000 tons. In 2016, two new machining

production lines for high-end cylinder head products were built. In 2017, the new aluminum alloy cylinder head casting and machining production line was launched, with 300000 units in phase I project. In 2018, the cleaning department of machining products was comprehensively transformed and upgraded. The company's R & D and manufacturing technology level is rising: Fast new product development. Years of specialization has tempered the product development team. There are full-time product development

departments in domestic and foreign markets and main engine product development departments, which has improved the skill level of employees. The company has set up a special production line for new cylinder head products and in-process product improvement, which can ensure that the speed of new product development is synchronized with and ahead of the main engine factory and market,

and ensure that the development of two valve cylinder head can be completed within 2 months The development period of four valve cylinder head shall be completed within 4 months. Excellent detection means. It has international excellent testing equipment and a complete range of physical and chemical, measurement and airway performance testing methods. Professional focus to form

characteristics. The company has long been committed to the construction of corporate culture and quality culture, people-oriented and pay attention to the growth of staff. Specializing in cylinder head for 26 years, it has excellent process technologies such as thin-wall gray cast iron, vermicular cast iron, aluminum alloy low-pressure and gravity casting, machining and so on. It has

system capabilities from research and development, mold design and manufacturing, precision casting to precision machining, so as to realize modular and on-time delivery and provide one-stop services for partners. The company adheres to the quality policy of "building a business with integrity, building a quality culture and creating value for customers, families and society", adheres to the development path of "specialization, scientization and internationalization", wholeheartedly improves the cylinder head

products, and wholeheartedly provides better products and services for the development of internal combustion engine industry!